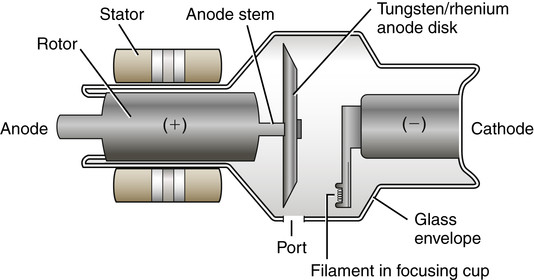

X Ray Tube Insert

X RAY TUBE

X-ray

tubes are vacuum tubes that convert incoming electrical power into X-rays. The

availability of this controllable X-ray source created the field of

radiography, the imaging of partially opaque objects with penetrating

radiation. In contrast to other sources of ionizing radiation, X-rays are only

produced when the X-ray tube is energized. X-ray tubes are also used in CT

scanners, airport baggage scanners, X-ray crystallography, material and

structural analysis, and industrial inspection. Growing demand for

high-performance computed tomography (CT) scanning and angiography systems has

driven the development of high-performance medical X-ray tubes.

X RAY TUBE PARTS

1.

Cathode X-ray tube

As

a complementary component to the anode, the cathode has a negative charge that

is released during operation, and it points towards the anode for further

projection. First, you'll find two other components attached to the cathode,

which are the focusing cup and the filament.

These

two connected elements are responsible for generating electrons and directing

them to the anode, generating a lot of heat in the process. Fortunately, the

cathode is made of a molybdenum-nickel alloy, a material that has high heat

resistance.

The

problem is that the size of the X-ray beam produced and projected by the

cathode depends on the size of the focal spot set by the technician operating

the machine.

2.

Glass envelope

The

glass envelope is an essential vacuum-filled part of the X-ray tube housing and

contains the components needed to generate X-ray energy. Typically, these

components consist of an anode, cathode, filament coil, focusing cup, and

focusing coil. In addition, the glass enclosure is made of Pyrex glass, suitable

to withstand the enormous heat generated during radiant production.

However,

the generation of radiation creates a tremendous amount of heat, which causes

the tungsten material used for the anode to evaporate, creating some deposits

on the glassware. These deposits then start to build up and over time can

become an obstacle to radiation production and proper projection.

3.

Focus coil

The

focusing coil is an attachment to the focusing cup that helps ensure that the

focusing cup guides electrons accurately from the cathode to the anode at a

predetermined point. While the predetermined point of the anode, also known as

the focal point, redirects radiation to the test sample, failure of the

focusing coil reduces the efficiency of the focusing cup to direct radiation to

the focal point on the anode.

4.

Anode (target)

One

of the most important components of an X-ray tube is the anode. The anode acts

as a complementary component to the cathode, but functionally, it attracts

electrons from the cathode once the X-ray machine operator presses the exposure

button. However, the anode itself is positively charged and usually generates a

lot of heat during the operation of any X-ray machine.

This

heat is responsible for making anodes using highly heat-resistant materials

like tungsten. However, the anode's disk rotates very fast to spread the heat

generated over its entire surface, avoiding the heat being concentrated in a

specific location. But more importantly, the anode acts as a target for

electrons from the cathode, at an angle that helps project the electron beam to

the detector.

Regardless,

if the anode spin fails, the damage to come will be enormous. Although tungsten

can handle a lot of energy, it cannot prevent damage to the anode even if it is

not rotated during the operation of the X-ray machine.

5.

Tube window

Inside

the glass envelope of the X-ray tube housing there is an important opening, not

more than 5 cm wide, called the X-ray tube window. The importance of this tube

window cannot be overstated, as it remains the only opening through which any

radiation generated can exit the glass enclosure. It also ensures that nearly

all the electron beam needed to reach the sample under inspection gets there.

However,

a small fraction of the radiation does not leave the glass envelope and is

eventually absorbed by the glass envelope, ultimately reducing the efficiency

of the glass tube. But the good news is that the glass material can be replaced

to restore the efficiency of the glass enclosure.

6.

Filament holder

If

the two most important parts of an X-ray tube are the cathode and anode, then

it is safe to say that the filament holder is the next most important part of

the X-ray tube. The reason is that the filament holder holds the X-ray

energy-generating filament in place, ensuring that it doesn't fall off during

operation.

Depending on the size of the test sample, the filament should produce enough radiation to penetrate the material, and sometimes when the material is so large, the energy can be enormous. Nonetheless, the filament holder ensures that there is no bridge between the filament and the power supply, ensuring that the right amount of energy reaches the filament.

7.

Cooling medium oil

During

X-ray machine operation, the rotor and anode disks can rotate at speeds up to

3,200 rpm, generating excessive heat in the process. Likewise, when radiation

from the filament strikes the rotating anode disk, the heat builds up further,

sometimes reaching extremely high levels. Cooling is very important to keep

your machine working at its best. Therefore, cooling oil is provided to

dissipate this heat. But that's not all. Since both the cathode and the anode

are charged, the cooling oil also acts as an insulating medium to prevent

electric shock.

8.

Guide coil

For

the power to reach the stator and rotor, the wires are passed through

insulating flexible coil material called lead coils. The basic function of the

guide coil is to enable electrical connections to navigate the irregular shape

of the X-ray tube and to insulate other components in contact with these

connection elements.

9.

X-ray tube housing

Typically,

X-ray tube assemblies are classified as either internal or external. However,

the outer components are usually the enclosures that keep the inner components

contained within the tube, simply because the radiation generated travels in

different directions within the X-ray tube. The X-ray tube housing is a metal

container that prevents leakage of radiation generated inside the X-ray tube.

Additionally,

the lead lining inside the enclosure ensures that the operator and others

around the machine are not exposed to any radiation exposure. Best of all,

because of the high voltage required to generate X-ray radiation, the enclosure

acts like an insulating wall, preventing the operator from getting

electrocuted.

10.

Induction stator

While

the anode and cathode are complementary, the rotor and induction stator also

appear to have this relationship. An induction stator is an electric motor that

acts as a power for the rotor to spin at sometimes very high speeds as it

provides the electricity needed for that activity. Most of the time, the stator

uses the induction method, which also uses a set of coils to induce a strong

magnetic field to generate the electrical energy needed to rotate, hence the

name induction stator.

11.

X-ray tube holder

An

X-ray tube holder is simply an external accessory that supports the components

of the X-ray tube as a unit without falling apart during operation. Some of

these supports include the housing and all its accessories such as screws,

anchor plates and metal bars. These elements ensure the rigidity and robustness

of the X-ray tube.

However,

no matter how securely the X-ray tube holder holds the X-ray tube in place,

these elements always need to be checked during regular and routine maintenance

activities to ensure they remain intact.

12.

Rotor

The

rotor is a very critical part of the X-ray tube as it holds the anode disk in

place before, during, and after any X-ray operation. The anode disk can be

rotated very fast depending on the size of the sample being examined and the

required radiation intensity. Thus, the rotor ensures that during these

high-speed operations, the disc is well-supported and rotates according to the

set speed.

The rotor and the anode disk are rigidly connected by the anode disk. However, while the anode disk is made of molybdenum, the rotor is made of copper as its body is not exposed to any radiation. High-strength ball bearings in the rotor make rotation easy and smooth.